In our introduction to packaging science blog, we highlighted career opportunities in the packaging industry. One of the most popular careers in the field of packaging is that of packaging engineer / designer. Packaging engineers have multiple responsibilities, including but not limited to designing, developing, testing, and optimizing packaging designs for virtually any product you can think of.

Those in the industry know that consumer demand and regulatory shifts make packaging an incredibly dynamic field of study with opportunities to learn something new everyday. In the spirit of continued learning, we decided to put together a list of the five skills that we recommend packaging engineers develop in 2025—from industry newcomers to seasoned veterans.

1. Life Cycle Assessment (LCA)

Consumers and regulators alike are sounding the call for sustainable packaging solutions, but packaging engineers know this is a complex endeavor. Navigating the trade-offs between different packaging materials, processes, and designs from an environmental sustainability perspective is no easy feat, however, life cycle assessments (LCA) can provide the data to point packaging engineers in the right direction.

A life cycle assessment (LCA) is a method to quantify the environmental impacts of a product or package throughout its entire lifecycle—from raw material extraction (cradle) to disposal (grave). This is achieved in four key stages of an ISO 14040/14044 compliant LCA that include:

Define Goal and Scope

Life Cycle Inventory (LCI)

Life Cycle Impact Assessment (LCIA)

Interpretation and Analysis

LCAs measure environmental impacts far beyond carbon emissions, with the European Union’s Product Environmental Footprint (PEF) standard measuring sixteen different impact categories: Climate Change (GWP), Ozone Depletion, Human Toxicity (Cancer), Human Toxicity (Non-Cancer), Particulate Matter, Ionizing Radiation, Photochemical Ozone Formation, Acidification, Eutrophication (Marine), Eutrophication (Terrestrial), Eutrophication (Freshwater), Eco-toxicity (Freshwater), Land Use, Water Use, Resource Use (Fossils), and Resource Use (Minerals and Metals). In other words, conducting an LCA with this standard can help your organization quantify the impacts related to each of these categories if you are able to gather the data from suppliers and touch points throughout your value chain.

LCAs can be used by packaging engineers to evaluate the environmental impacts of different materials, production processes, suppliers, etc. at the design phase, ensuring packaging solutions are as sustainable as possible and aligned with broader organizational sustainability initiatives and goals. LCAs can also be used to aid in packaging research and development, sustainability reporting and avoiding greenwashing, and eco-modulation and extended producer responsibility (EPR) compliance.

Interested in learning more about LCAs and how they can be a key sustainability tool for packaging engineers? To start, check out our Intro to LCA for Packaging Professionals blog. And if you are interested in formal training, check out our online Certificate of Sustainable Packaging (CSP) program—it contains an LCA module that teaches you how to evaluate primary, secondary, and tertiary packaging systems with a software designed to run packaging-related LCAs.

2. EPR Compliance and Eco-Modulation

As we highlighted above, LCAs are great tools to assist in extended producer responsibility (EPR) for packaging compliance and eco-modulation. Even if you aren’t in your organization’s compliance department, we feel strongly that all packaging engineers and professionals can benefit from developing an understanding of these laws and how they are set to impact individual organizations and the packaging value chain at large.

EPR for packaging is a regulatory approach making the producers of packaging and packaging-related products responsible for managing the entire life cycle of packaging they introduce to the market—from conception to end of life. In practice, it shifts the burden of funding and managing externalities of packaging waste from tax payers and municipalities to the producers themselves who will pay fees based on the kg/tons of specific materials sold into the market and other reporting / compliance tasks.

Our research has found that 60+ nations around the world have EPR for packaging laws; you can learn more about these programs in our EPR for Packaging index that includes nine research articles on the topic.

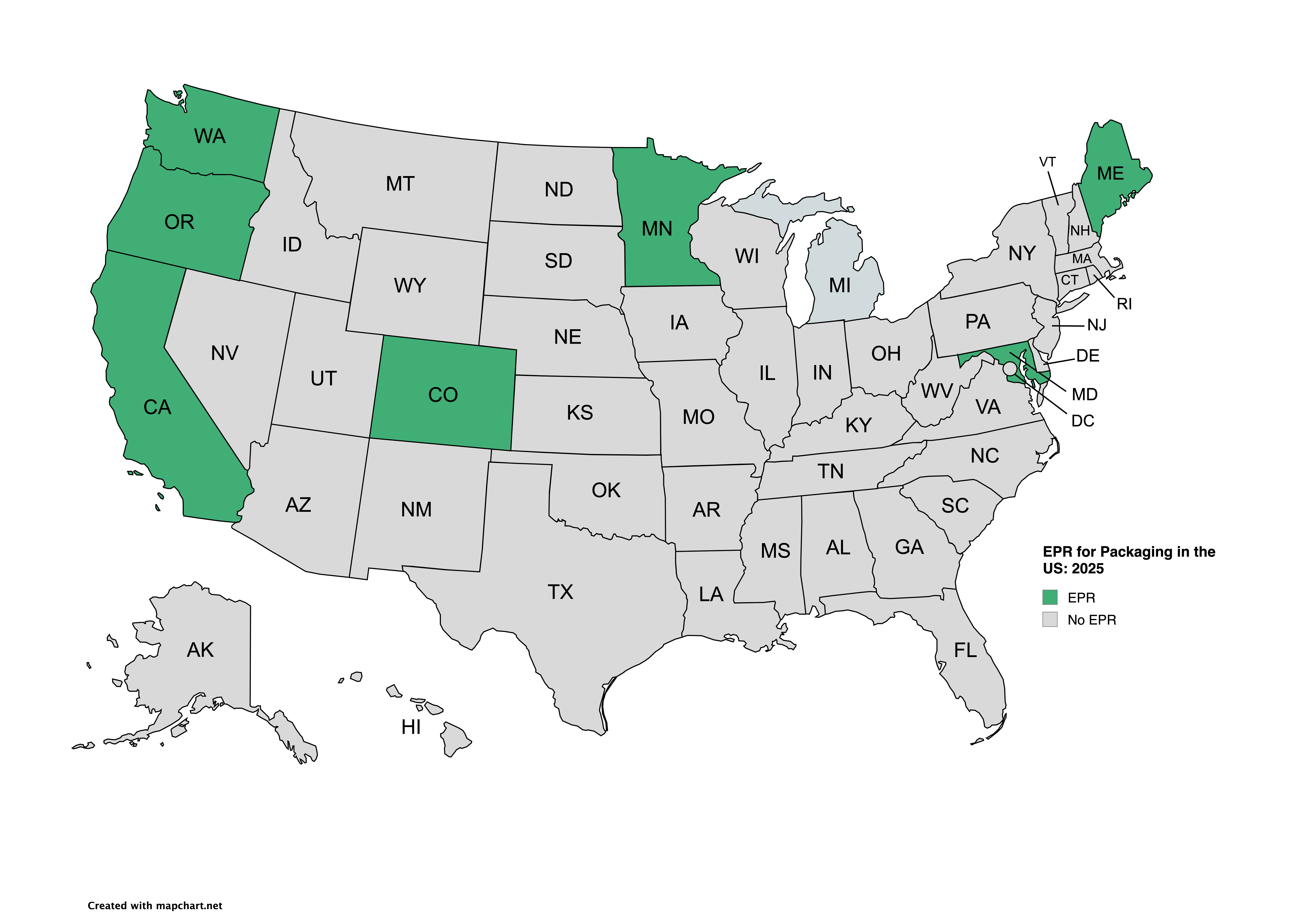

In the United States, seven states have passed EPR for packaging laws, including Maine, California, Oregon, Colorado, Minnesota, Maryland, and Washington. All of these programs have different requirements, implementation timelines, and more. However, all programs utilize producer responsibility organizations (PROs) to manage and register the producers, collect and redistribute funds, and ensure the EPR program is meeting its goals. You can read more about these programs in our blog here.

Another facet to EPR that packaging professionals should be aware of is eco-modulation, also known as eco-modulated fees. We wrote a research article on this topic back in November; in short, eco-modulation in EPR programs empowers PROs and state departments to adjust and lower fees to incentivize packaging producers to minimize waste and use more sustainable materials at the packaging design phase.

The philosophy behind eco-modulation lies in the belief of the mechanism to catalyze “systems change” for more sustainable, recyclable, and compostable packaging, rather than paying fees to cover recycling costs and continuing with business as normal.

Additionally, many state departments recognize that the largest percentage of a package's environmental impact is related to production, not disposal. Oregon’s Department of Environmental Quality highlighted this notion in their Guidance to Ecomodulate Fees guide:

“Evidence suggests that some recyclable items may be more impactful than non-recyclable alternatives, even when the benefit of recycling is accounted for, and even if recycling is maximized. This is because the environmental impacts of production are often many times larger than the impacts of disposal, and because recycling can never fully mitigate the impacts of production.”

To support this belief, Oregon is planning to include LCAs as tools to qualify for eco-modulated fees, as Packaging Dive reports. The article notes:

“The top 25 producers are required to create LCAs for 1% of their products sold or distributed in the state every two years, while smaller companies can voluntarily submit LCAs if they want to earn a reduction on the fee they owe. Both kinds of companies could earn a discount if they opt to take their LCAs a step further and use them to prove they have reduced the environmental impact of a product.”

As mentioned, we cover all of this and more in a research article written by our team last fall, however, we wanted to leave you with a map of the states with EPR programs that have intentions to include eco-modulation as part of their programs, currently all seven of them.

Stay tuned for emerging details about what eco-modulated fees might look like in practice as these programs grow closer to implementation dates, with Oregon expected to be the first in July of this year.

3. Implementing AI Tools in Packaging Design Workflow

The use of artificial intelligence tools is a hot and divisive topic in virtually every sector, including the colossal $1 trillion USD packaging industry. Regardless of your feelings on AI, one thing is certain—it is here and must be reckoned with.

At the Packaging School, we recognize that AI is not a tool that should be used in isolation or as a replacement for human designers. At the same time, it can be a vital tool to help in brainstorming, ideation, and other tasks in a typical packaging design workflow.

Our team has written a handful of blogs exploring how to use generative AI software like Midjourney, Fotor AI, Canva Magic Studio, Adobe Express, OpenAI, and Pacdora to aid in brainstorming and creating packaging design mockups with ease.

Our articles on AI tools for packaging design, (e.g., Top AI Tools for Packaging Design), are amongst the most popular on our site, speaking to the exponential growth of the interest surrounding this topic. Understanding how to master these tools is one of your first steps towards protecting yourself from AI disrupting your role in the packaging industry—it is not likely that AI will take your job, but someone who knows how to leverage AI better than you just might!

You can read more on how to use AI in packaging design tasks in our AI content index here.

4. Evaluating Alternative Materials

Another essential skill packaging professionals should have is knowing how to evaluate the efficacy, sustainability, and scalability of emerging and alternative materials that pop up from university research and startups.

Those in the packaging industry witness new innovations on, what seems to be, a daily basis—from seaweed biopolymers to mycelium-based styrofoam alternatives. But how do professionals navigate which materials are here to stay, which are aspirational but not scalable, and which should not even be considered?

For starters, having a solid foundation in packaging science, including an understanding of how different packaging materials perform in terms of product protection, sustainability, and more is essential. All materials have trade-offs, and being able to articulate the performance trade-offs of new, emerging materials compared to conventional materials like PET, aluminum, paper, etc. is the first step in the right direction.

Furthermore, a deep understanding of packaging science and the packaging development process can also help you gauge which emerging materials can be implemented into existing machinery and which will include major capital expenditures to create the infrastructure for these materials to be produced at scale.

For example, ISTA has developed a sustainable packaging process guideline which provides rationale for sustainable packaging, recommended sustainable packaging metrics, and a standardized process guidance (including recommended templates) for organizing and documenting a complete sustainable packaging development program.

Additionally, it is important for packaging professionals to understand how to navigate the environmental trade-offs between emerging materials and conventional materials. There are many tools to achieve this, but one of the most reliable methods is using LCAs to understand how different packaging systems perform in sixteen different environmental impact categories. New materials that emerge from labs and startups are exciting and seem to have consumer interest behind them, but a true packaging professional knows to take this analysis a step further by exploring the performance and environmental trade-offs associated with each material.

It is also important for professionals and packaging teams to assess which materials are scalable and can meet the current output of conventional materials. Understanding machinery, demand, and more is a great start, but we invite packaging professionals to think larger.

When looking at alternative materials, such as seaweed, think about the feedstocks and sourcing practices. Ask yourself questions like: Is there currently enough of a raw material supply to have this material replace what we are already using? Are there standards and third party bodies in place to ensure we can source this material ethically and responsibly? If you were to adopt the material, would consumers recognize that it is compostable or would you need a campaign to educate consumers to participate in proper disposal?

As you can see, these decisions are complex and require critical analysis. We recommend creating an internal process to evaluate new materials and sort which are a good fit for your packaging material mix and which are aspirational but not truly a viable alternative.

You can learn more about the packaging management and development process in our online Certificate of Mastery in Packaging Management (CMPM) program. This program includes a semester-long project that guides students on how to develop a process to launch new packaging innovations through a ten-step, iterative process we call the Packaging Development Plan (PDP).

5. Understanding Smart and Active Packaging Solutions

Another emerging space in the packaging industry that professionals, especially those at CPG and food and beverage brands, should stay on top of is smart and advanced packaging systems.

Smart packaging refers to product packaging designed to include interactive technology and other components that help communicate vital information to consumers at the point of purchase. An example is using a QR code on a package that directs consumers to real-time recycling information based on their location (through zip code or location services)—like the goal of the How2Recycle Plus label.

Smart packaging transforms packaging from a means of product protection and branding to a way for consumers to engage with a brand and move through the purchasing process with real-time information, moving packaging from a “silent salesperson” to an “active” salesperson.

On the other hand, active packaging includes components and technology used in food, beverage, and pharmaceutical packaging to help extend shelf life, control moisture levels, reduce toxic components, and more. This can include oxygen scavengers, carbon dioxide emitters and absorbers, and more.

An example is a groundbreaking water-based cysteine component developed by researchers at Chalmers University in Sweden that works to interact with canned tuna products to decrease mercury content—by up to 35% in some cases (Packaging Gateway). While this is a complex example of active packaging, there are more simple types like moisture scavengers for mushroom, berry, and meat packaging that extend shelf life by managing moisture content and maintaining ideal appearance.

As you can see, smart and active packaging solutions add a layer of often complex technology, and developing an understanding of these technologies can empower you as a packaging engineer to explore opportunities to improve product performance, contribute to sustainability by increasing shelf life and recycling education, and more with their use.

Grow Your Skills through Microlearning

Interested in expanding your knowledge of these five skills and others, but feel you don’t have time in your busy professional life? Look no further than our 85+ online, asynchronous microlearning courses that cover the art, science, and business of packaging!

Learn more about our dozens of courses and online certificate programs in packaging science, management, sustainable packaging, and automotive packaging here.

By signing up you indicate you have read and agree to our Terms of Use. Packaging School will always respect your privacy.