Recycling Innovation in the Packaging Industry

Introducing the Packaging School’s Packaging Innovation Dashboard series! We will be highlighting stories from how the top brands are innovating in different areas related to packaging—starting with recycling innovation.

In this edition, we highlight how West Virginia University, Glacier AI, and Taco Bell are working to implement innovative solutions in the realm of recycling.

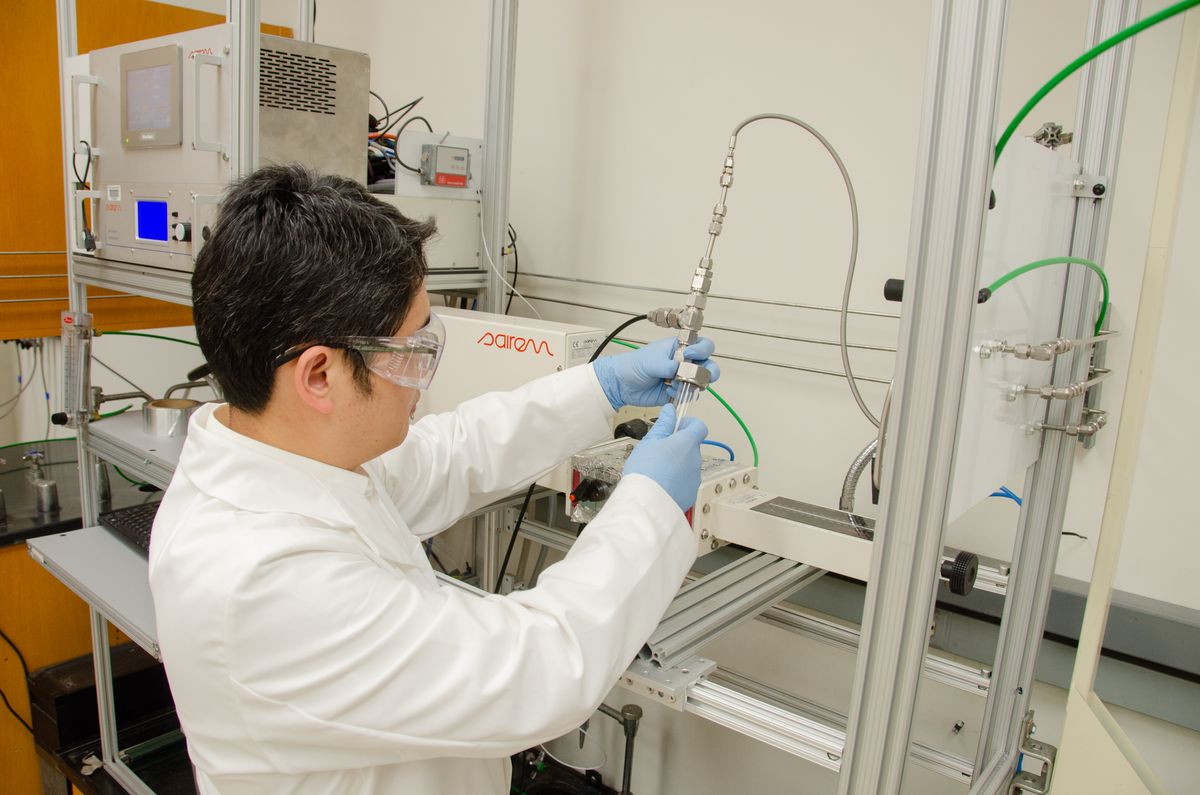

West Virginia University | Polypropylene (PP) Recycling

Photo from West Virginia University

Yuxin Wang and researchers at West Virginia University (WVU) have developed a groundbreaking method to recycle polypropylene (PP) plastic using microwave technology—allowing the team to recover the chemical compound (propylene) and enable use beyond “recreating the original item.”

According to Packaging Gateway, WVU’s technique involves “using microwaves to heat a catalyst material that then transfers the heat to the PP waste, breaking it down into its original chemical components.” Wang emphasizes that this method allows “precise control over heating” and runs at lower temperatures compared to conventional recycling (300 degrees Celsius vs. 600–700 degrees Celsius).

Wang stated:

“In recycling, you crush a water bottle into small pieces and then use those pieces to build a bottle again. Recycling limits your utilization. We want to generate chemicals that not only can be used to manufacture polypropylene again but also can be valuable in other reactions.”

Read more on the innovative PP recycling process here.

Story from Packaging Gateway

Glacier | Vision-Based AI to Boost Recycling

Those in the packaging and supply chain world know that one of the largest challenges facing recycling and waste management is data availability—Rebecca Hu and Glacier are working to change that through the power of artificial intelligence (AI).

At a recent Packaging Recycling Summit hosted by Packaging World, Hu joined the stage with Nicholas Ellis of Amazon and Greg Corra of Colgate-Palmolive to explain how these firms are using Glacier’s AI software to collect recycling related data for tubes, bioplastic packaging, and more.

Glacier’s work with Colgate-Palmolive includes developing a “first-of-its-kind vision-based AI model capable of identifying and sorting both toothpaste tubes and non-toothpaste tubes in real-time.” This technology was installed in Colgate’s partner MRFs and uses AI cameras to capture continuous images of the tubes on conveyor belts. Hu explains that, “Colgate and partner MRFs can log in to a dashboard and learn what’s happening on a given belt over the last year, or even the last minute.”

Hu stated:

“I know it can be really hard to tell what’s real and what’s just hyped when it comes to AI. There’s a lot of news out there, and as someone who’s worked in this space for many, many years, I can tell you what I’m seeing on the front lines. The type of AI progress we’re sharing here today is really impactful and probably a little bit history making. And it’s the result of many, many months of really hard, invisible work and collaboration between Glacier and Colgate and our MRF partners. So this work, I have to say, at the end of the day, is worth it.”

Read more about how Glacier is transforming the availability and quality of recycling data at MRFs with AI and their work with Colgate and Amazon here.

Story from Packaging World

Taco Bell x TerraCycle | Sauce Container Recycling Program

Photo from Taco Bell

Did you know that Taco Bell and TerraCycle have been working to increase the amount of fast food packaging that is recycled since 2021?

In 2021, Taco Bell and TerraCycle came together to create the Taco Bell Sauce Container US Recycling Program—an initiative to boost fast food packaging, particularly sauce packets.

The partnership came after the realization that Taco Bell was responsible for ~8.2 billion hot sauce packets entering landfills each year, as small sauce packets are traditionally harder to process and recycle in many MRFs. The program boosted Taco Bell’s recycling rates, and they began accepting all sauce packets in 2022.

In April of this year, Taco Bell and TerraCycle announced that the program will now accept items like, “sauce dipping cups, souffle cups and lids, and coffee creamer pods.”

You might be wondering . . . how does it work? Plastics Today lays it out in four steps:

Any entity (individual, school, institution, etc.) signs up online at the “Taco Bell Sauce Container US Recycling Program” landing page on TerraCycle’s website.

Participating entities collect used sauce packets and other accepted items in a recyclable box.

When a participant's box is full, they “log in to their TerraCycle account to download and print a free UPS shipping label and then ship the labeled package to TerraCycle for recycling.”

Once TerraCycle receives the box, the organization separates and organizes the waste by material type and cleans the waste. Next, “the materials are then melted into hard plastic pellets that can be remolded into new products, such as picnic tables.”

Read more on how Taco Bell and TerraCycle are collaborating to boost sauce packet recycling in this Plastics Today article.

Story from Plastics Today

Learn more about Sustainable Packaging

Ensuring packaging is recyclable, contains recycled content, and boosts collection and sorting infrastructure (hopefully through EPR programs) is an important part of the push for more sustainable packaging, but it is just one piece of the puzzle.

Learn how to evaluate the full life cycle of a packaging system in our online Certificate of Sustainable Packaging (CSP) promo, which includes a module that teaches you how to conduct a life cycle assessment of a provided packaging system. Learn more here.

By signing up you indicate you have read and agree to our Terms of Use. Packaging School will always respect your privacy.