Guide to Life Cycle Assessment Impact Categories for Packaging: EU Product Environmental Footprint (PEF)

Sixteen LCA Impact Categories in the EU's Product Environmental Footprint (PEF) Method

Navigating the trade-offs of different packaging materials and processes from an environmental impact perspective is one of the largest challenges facing packaging teams to date. One of the most widely used methods to help navigate trade-offs from a scientific, data-driven approach is the Life Cycle Assessment (a.k.a. LCA or Life Cycle Analysis).

One of the most important parts of an LCA is grouping complex environmental data from a life cycle inventory (LCI) into impact categories that can be calculated in the life cycle impact assessment (LCIA) phase.

LCA Impact Categories group related environmental impacts into categories to help make sense of LCA data and results. A common impact category is global warming potential (GWP), which represents the total emissions impact of a packaging system by translating all emissions (Co2, So2, CH4, etc.) into a common unit a measure (Kg Co2e). Impact categories simplifying the calculations and interpretation of results, allowing you to find impact hot spots with ease.

How you organize and calculate impact categories is dependent on the life cycle impact assessment method selected for the LCA—one of the most common is the European Union's Product Environmental Footprint (PEF) method.

In this guide, we will explore the sixteen impact categories in the PEF and how different packaging processes can contribute to each impact.

1. Global Warming Potential (GWP)

Global Warming Potential groups the emissions and climate change impacts related to a packaging system, converting different emissions sources to a carbon dioxide equivalent to represent the total emissions impact.

How is it measured?: 1 kilogram of carbon dioxide equivalent (Co2e)

Ex. 1 kg of methane = 28–36 kg of Co2e

Packaging processes that cause emissions:

Extraction of raw materials

Manufacturing and processing

Transportation and distribution

End-of-life and disposal

Available on Trayak's COMPASS packaging LCA software

2. Ozone Depletion Potential

.jpg)

Ozone Depletion Potential measures the potential of a packaging (or product) system to contribute to the depletion of the ozone layer, which works to protect humans and plants from harmful UV radiation.

How is it measured?: kilograms of Freon-11 equivalent (CFC-11 equivalent)

Packaging processes than can lead to ozone depletion:

Refrigeration in transport or storage

Production of foams and foam-based packaging materials

Other manufacturing processes

3. Human Toxicity (Cancer-Effects)

.jpg)

Human Toxicity (Cancer-Effects) is used to group the impacts related to the potential of a packaging system to emit externalities that can cause harm to human health (including cancer) through exposure in air, water, etc.

How is it measured?: Comparative Toxic Unit for humans (CTUh)—USEtox model

Packaging processes that can cause Human Toxicity (Cancer-Effects):

Manufacturing waste and runoff

Exposing consumers to PFAS through packaging and coatings

Manufacturing and mining activities

Available on Trayak's COMPASS packaging LCA software

4. Human Toxicity (Non-Cancer Effects)

Human Toxicity (Non-Cancer Effects) measures the impacts of a packaging system that can emit externalities that introduce toxins to water, air, etc. and cause human health effects upon exposure, excluding toxins that can cause cancer.

How is it measured?: Comparative Toxic Unit for humans (CTUh)—USEtox model

Packaging processes that can cause Human Toxicity (Non-Cancer Effects):

Manufacturing activities that negatively impact air quality (leading to increased asthma rates, heart issues, etc.)

Exposing consumers to microplastics throughout the life cycle of a package

Other manufacturing and mining processes

Available on Trayak's COMPASS packaging LCA software

5. Particulate Matter

Particulate Matter (PM) is an impact category that represents the potential of a packaging system to emit particulate matter (and precursors like nitrous oxide and So2) during its life cycle, leading to chronic health conditions to those exposed.

How is it measured?: Disease incidence per kg of PM2.5 emitted—essentially measure the change in mortality rate due to particulate matter emissions.

Packaging processes that cause Particulate Matter emissions:

Transportation of packaging throughout the value chain

Manufacturing and industrial processes

Energy production to power packaging manufacturing operations

6. Ionizing Radiation

Ionizing Radiation represents the potential of a packaging system to emit externalities that can expose humans to radioactivity, leading to negative health effects.

How is it measured?: equivalent of kilobecquerels of Uranium 235 (kg U23g equivalent)

Packaging activities that can lead to ionizing radiation: Not as relevant, unless you power your packaging operations / manufacturing with nuclear energy, then improper handling of waste could lead to exposure.

7. Photochemical Ozone Formation

Photochemical Ozone Formation groups the impacts of a packaging system that can contribute to the formation of photochemical ozone formation (smog), which can lead to negative health effects.

How is it measured?: kilograms of Non-Methane Volatile Organic Compounds (kg NMVOC equivalent)

Packaging processes that can contribute to smog formation:

Emissions from transportation and distribution of packaging

Emissions from manufacturing activities

Industrial activities and mining

Emissions from energy production to power packaging operations

8. Acidification

Acidification measures the potential of a packaging system to emit externalities that can be absorbed into water and soil and lead to acidification of ecosystems, harming marine life and disrupting food chains.

How is it measured?: equivalent of moles of hydron (mol H+ equivalent)

Packaging processes that can cause Acidification:

Using sulphur-based fuels to transport packages throughout the value chain

Generation of electricity to power packaging operations

Other manufacturing processes

9. Eutrophication (Terrestrial)

Eutrophication (Terrestrial) considers the potential of a packaging system to emit nitrogen and phosphorus (macronutrients) into terrestrial ecosystems, leading to overgrowth and undergrowth of certain plant species and decline in biodiversity.

How is it measured?: equivalent of moles of nitrogen (mol N equivalent)

Packaging processes that cause Terrestrial Eutrophication:

Sourcing raw materials from agricultural byproducts (use of fertilizers)

Wastewater discharge from manufacturing facilities

Sourcing wood from areas prone to deforestation (depletion of buffer zones that prevent fertilizer runoff)

Combustion of fossil fuels through transport of the package throughout the value chain

10. Eutrophication (Marine)

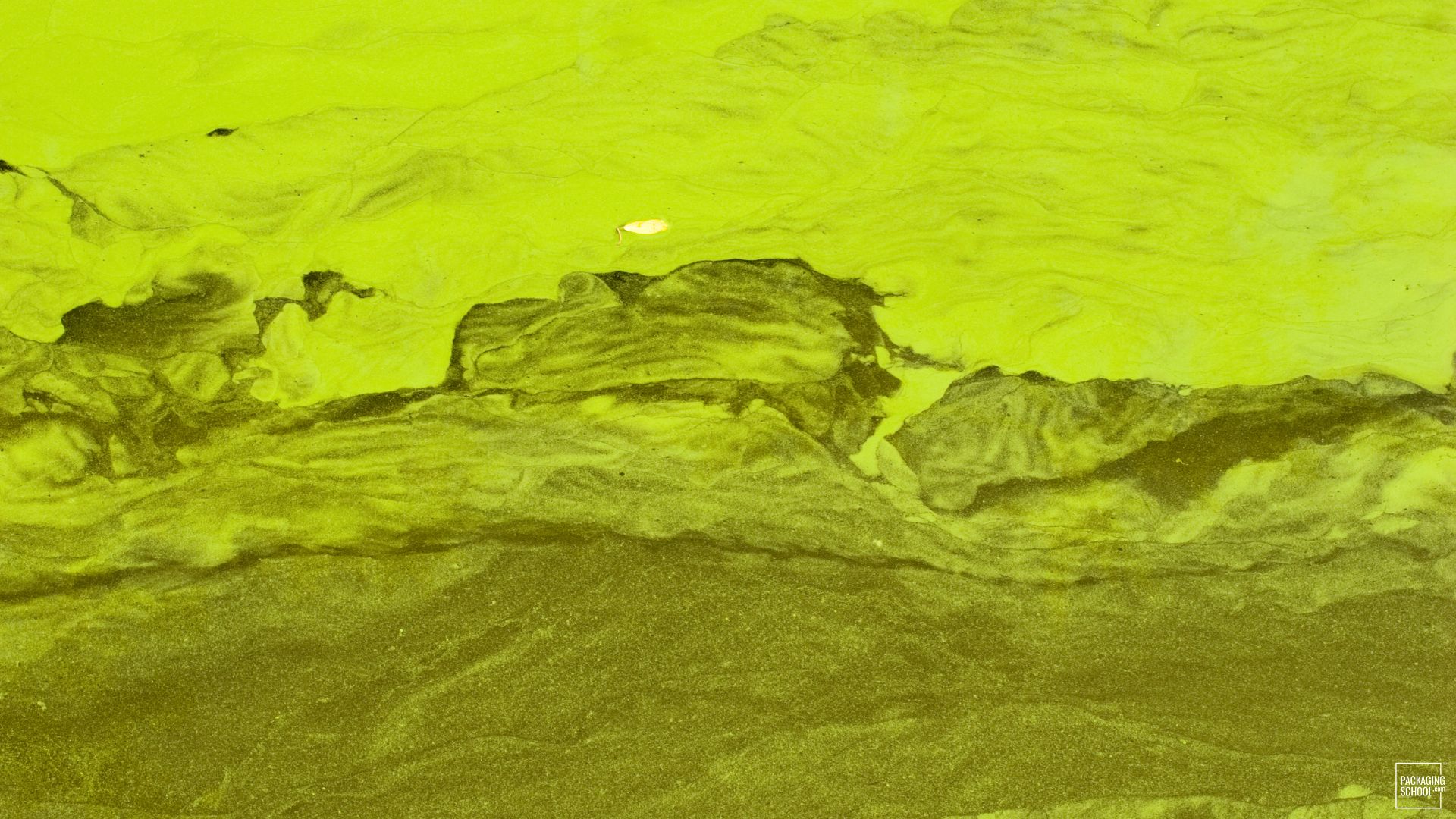

Eutrophication (Marine) measures the potential of a packaging system to contribute to eutrophication in marine ecosystems through the introduction of excess nitrogen and phosphorus (macronutrients), leading to toxic algae blooms that lead to lowering dissolved oxygen levels which create "dead zones."

How it is measured?: kilograms of nitrogen equivalent (kg N equivalent)

Packaging processes that can contribute to Marine Eutrophication:

Sourcing raw materials from agricultural byproducts (use of fertilizers)

Wastewater discharge from manufacturing facilities

Sourcing wood from areas prone to deforestation (depletion of buffer zones that prevent fertilizer runoff)

11. Eutrophication (Freshwater)

Eutrophication (Freshwater) considers the potential of a packaging system to contribute to eutrophication in freshwater ecosystems, leading to excess algal blooms and dead zones, similar to marine eutrophication.

How is it measured?: equivalent of kilograms of phosphorus (kg P equivalent)

Packaging processes that can contribute to Freshwater Eutrophication:

Sourcing raw materials from agricultural byproducts (use of fertilizers)

Wastewater discharge from manufacturing facilities

Sourcing wood from areas prone to deforestation (depletion of buffer zones that prevent fertilizer runoff)

Manufacturing processes that emit phosphorus

Available on Trayak's COMPASS packaging LCA software

12. Ecotoxicity (Freshwater)

Ecotoxicity (Freshwater) is an impact category that considers the potential of a packaging system to emit externalities that lead to toxic conditions in freshwater ecosystems, leading to biodiversity loss and ecosystem disturbances.

How it is measured?: Comparative Toxic Unit for ecosystems (CTUe)—USEtox model

Packaging processes that can lead to Freshwater Ecotoxicity:

Sourcing raw materials from agricultural byproducts that use chemicals in agricultural processes

Using toxic chemicals in plastics that leach into waterways

Microplastic pollution from plastic packaging and improper disposal

Certain manufacturing processes

Available on Trayak's COMPASS packaging LCA software

13. Land Use

Land Use is an impact category that measures transformation and use of land as a result of a packaging systems value chain, leading to biodiversity loss, erosion, the exacerbation of other environmental impact categories through runoff, and other impacts.

How is it measured?: Measured based on a "composite indicator" of four different soil properties—biotic production, erosion resistance, groundwater regeneration, and mechanical filtration.

Packaging processes that contribute to Land Use:

Sourcing raw materials from agricultural byproducts that are farmed in monocultures

Sourcing wood from areas prone to deforestation

Industrial processes that create pollution that negatively impact the four soil properties above

14. Water Use

Water Use considers the potential of a packaging system to drive the depletion of water resources (lakes, groundwater, rivers, etc.), particularly focusing on the scarcity of water in production regions.

How is it measured?: cubic meters of water use in relation to local scarcity of water

Packaging processes that contribute to Water Use:

Packaging manufacturing processes

Raw material extraction processes

Recycling and end-of-life processing

Available on Trayak's COMPASS packaging LCA software

15. Resource Use (Fossil Fuels)

Resource Use (Fossil Fuels) measures the amount of fossil fuels extracted in relation to a packaging systems life cycle. Fossil fuels covered by the PEF include coal, natural gas, and oil.

How is it measured?: through the conversion of the "amount of materials" to a megajoule (MJ) which represents 1 million joules

Packaging processes that can lead to Resource Use (Fossil Fuels):

The extraction of oil to create plastic packaging

Fossil fuels burned to transport packages throughout the value chain

Energy use to power packaging manufacturing operations

Available on Trayak's COMPASS packaging LCA software

16. Resource Use (Minerals and Metals)

Resource Use (Minerals and Metals) measures the extraction of finite metals and minerals related to the life cycle of a packaging system. The PEF notes that gold, silver, aluminum, and other metals must be extracted in a responsible manner to ensure supply for future generations, similar to fossil fuels.

How is it measured?: through the conversion of the "amount of materials" to a kilograms of antimony equivalent (kg Sb equivalent)

Packaging processes that can lead to Resource Use (Minerals and Metals):

Mining of metals (aluminum) for the production of metal packaging

Other manufacturing processes (raw materials for packaging machinery, etc.)

Available on Trayak's COMPASS packaging LCA software

Measure the Impact of Your Package with LCA

Now that you understand what a life cycle assessment can quantify, the next step is running one of these assessments on your own packaging systems to identify impact hot spots and areas for optimization.

Looking to run a packaging-related LCA to see how your packaging scores on impact categories like the sixteen above?

Check out our packaging LCA training module within our online Certificate of Sustainable Packaging program where we walk you through how to use a leading packaging-specific LCA software to evaluate your primary, secondary, and tertiary packaging systems. The software has the capability to quantify seven different impact categories: GWP, Water Use, Fossil Fuel Use, Freshwater Eutrophication, Mineral Resource Use, Freshwater Ecotoxicity, and Human Impact (Midpoint).

Interested on reading more on the role of LCA in the packaging world? Check out our index page here.

By signing up you indicate you have read and agree to our Terms of Use. Packaging School will always respect your privacy.