Dieline Design

Dielines are commonly designed using computer-aided drafting or CAD software to produce precise package templates. A modern dieline will commonly contain different layers such as structural and graphic layers, and CAD software can easily align these layers to allow for much faster design times than drafting by hand. To ensure functionality, these completed dielines are uploaded to drafting tables where the prototypes are made.

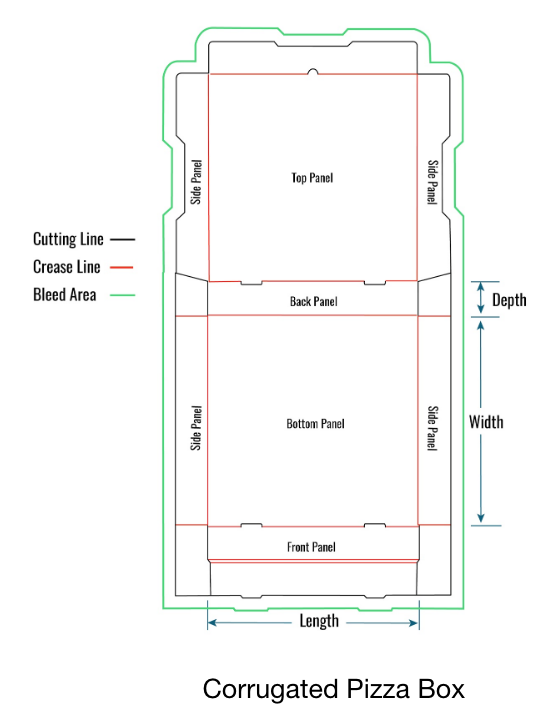

Die manufacturers use dielines to program the laser engravers which draw the die layout on the die board. Graphical dieline layers are denoted by ink color, and can then be used to produce the necessary printing plates for the printing process. Structural layers will include all details related to the structure itself, such as dimensions and locations of cut/crease/fold lines, and the gluing areas when applicable.

Cutting and creasing are the two main processes used to form corrugated containers, making it critical for them to be represented on the dieline. The flaps on a box must fold along a predetermined area, so they are scored to aid in folding. Other parts of a box or carton, such as the main profile or outline of the structure, may require full separation from the rest of the board. And still other areas may require perforations for tear tabs or for easy separation of components later in the process.

Another consideration when designing a dieline involves folding. When paper is folded, it loses some space on the inside of the fold while gaining space on the outside of the fold. With a regular sheet of paper, this change is so minimal it does not have much of an impact until it is folded several times. Because corrugated is much thicker, the outside gains and inside losses are much more apparent and need to be accounted for with what is called the “scoring allowance.” Corrugated will fold at its midpoint (except for certain double wall scenarios) so the scoring allowance is directly related to the caliper of the board.

Creating a dieline is necessary to the box making process—it’s the blueprint those on the manufacturing and production side of things use to build your package. Paying close attention to its details will help ensure your package looks and functions according to the original plan.

Want more information on the details behind dielines? Check out the packaging certificates we offer and you’ll get the chance to learn ALL about the design process!