The Evolution of Corrugated Timeline

Ever wondered about the history of corrugated? Let’s explore some significant dates that set the foundation for corrugated packaging to become the colossal giant that it is today!

950 BCE

The first writing material was introduced by the Ancient Egyptians. The material was made by pasting together thin layers of plant systems.

100 CE

The first authentic paper was introduced by the Chinese, made from bamboo and mulberry fibers.

1400s

The first paper mills began in Spain, Germany, and France.

1690

The first sheet paper mill in North America opened near Philadelphia.

1767

England imposed the Stamp Act to regain their loss of colonial paper exports. The act included a tax on all paper made in the colonies. Many believe this was fuel for the American Revolution.

The Industrial Revolution (the late 1700s to early 1800s) brought individual packaging into focus. As cities formed and rural work gave way to factories, goods were more efficiently mass-produced.

Shops opened, selling the mass-produced goods and creating a consumer society. As stores became larger and held a wider variety of products, shopkeepers no longer had the ability to have intimate knowledge of every item. For the first time, focus on package design became crucial. Packages began to not only inform the consumer but also sell the product.

1798

Alois Senefelder invented lithography, a printing technique made possible by methods of industrial production. Frenchman Nicholas-Louis Robert sparked the industrialization of paper by inventing the papermaking machine in the same year.

1803

The first continuous papermaking machine was patented.

1854

The first pulpwood was manufactured in England.

1856

The first known corrugated material was introduced and patented for sweatband lining in tall hats of Victorian Englishmen.

1871

Unlined corrugated first appeared as the packaging material for glass and kerosene lamp chimneys.

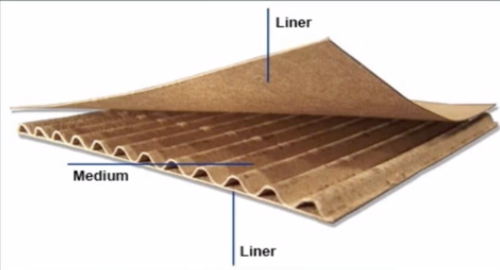

1874

A liner was placed on one side of the corrugated material to prevent flutes from stretching.

1894

Corrugated board is cut and slotted to produce the first box structures.

1895

Wells Fargo began using the corrugated boxes to ship their small freight.

1902

The first solid fiber boxes were developed.

1903

Corrugated was approved as a valid shipping material and used to ship cereals.

1909

Rubber printing plates were introduced, allowing for greater design creativity.

1914

Tariffs imposed on corrugated shipping containers were ruled discriminatory.

1919

Rule 41 was formed, which specified the minimum caliper and Mullen Burst Strength of individual facings.

1935

The Stein Hall Company reconverted the starch industry to starch adhesives. The process included replacing the cooked starch paste with a mixture of cooked and uncooked starch. They then applied heat at the glue line which caused the starch to solidify, creating an instant bond.

1944

Railroad rules changed to require the minimum combined weight of the facing versus caliper.

1957

Flexographic printing virtually replaced letterpress and oil-based ink printing.

1960s

The flexo folder-gluer was invented.

1968

Item 222 was first introduced, providing truck shipping rules.

1970

OSHA (The Occupational Safety and Health Act) was passed. This regulated packaging machinery and plant operations.

1972

The corrugated industry attempted to update Item 222 and Rule 41.

1973

The UPC (Universal Product Code) was first introduced.

1975

Congress directed the Department of Transportation (DOT) to control the distribution of hazardous substances.

1977

The Transportation Safety Act was amended to directly regulate manufacturers and vendors of hazardous materials.

1980s

Prepress emerged.

New developments in printing systems including the anilox roll and the plate-and-press design led the industry toward short-run, high-graphic products.

1990s

The Edge Crush Test was added to Item 222 and Rule 41 as an alternative to Burst Strength and Basis Weight. This allowed the manufacture of lighter weight liners.

“Quick change” multi-flute single face machines were developed, adding flute profiles while saving money and floor space.

Corrugated manufacturers belonging to the FBA (Fibre Box Association) came together in an unprecedented manner to defend their share of the produce packaging market. They developed a modular standard now known as the Corrugated Common Footprint.

2000s

The CCF (Corrugated Common Footprint) created a standard for product packaging that was formally adopted by both European and North American corrugated industries.

The large format digital press is introduced at the TAPPI CorrExpo.

Convenient equipment designed for short, automated, very fast setups with consistently high run speeds.

Advances made in RFID (Radio-Frequency Identification) memory, readability in tough applications, and read range.

Digital printing on corrugated became practical for short runs.

FBA (Fibre Box Association) published a recyclability standard, Voluntary Standard for Repulping and Recycling Corrugated Fibreboard Treated to Improve Its Performance in the Presence of Water and Water Vapor.

2010s

The first Life Cycle Assessment (LCA) for corrugated is developed and released by the Corrugated Packaging Alliance.

Equipment is available to create custom boxes on-demand.

The Future

Corrugated board is not going away anytime soon. Already in high demand, it is predicted to increase by 4% annually during the next 5 years.

However, there are factors negatively affecting the global corrugated market. The increasing price of raw material is forcing smaller players in the industry to shut their doors. This paves the way for larger corporations to merge, forming global giants in corrugated production. The volatile market may reduce demand and increase prices for corrugated moving into the 2020s.

Incredibly fast and efficient digital die-cutting will allow anyone to launch with custom packaging.

The corrugated industry will continue to go through changes as we seek to improve our methods of packaging and make this a substrate that is financially and environmentally sustainable.

If you think this timeline was helpful, you’ll LOVE our courses on packaging!

Click here to learn more about the many courses and certificates we offer at the Packaging School!

By signing up you indicate you have read and agree to our Terms of Use. Packaging School will always respect your privacy.